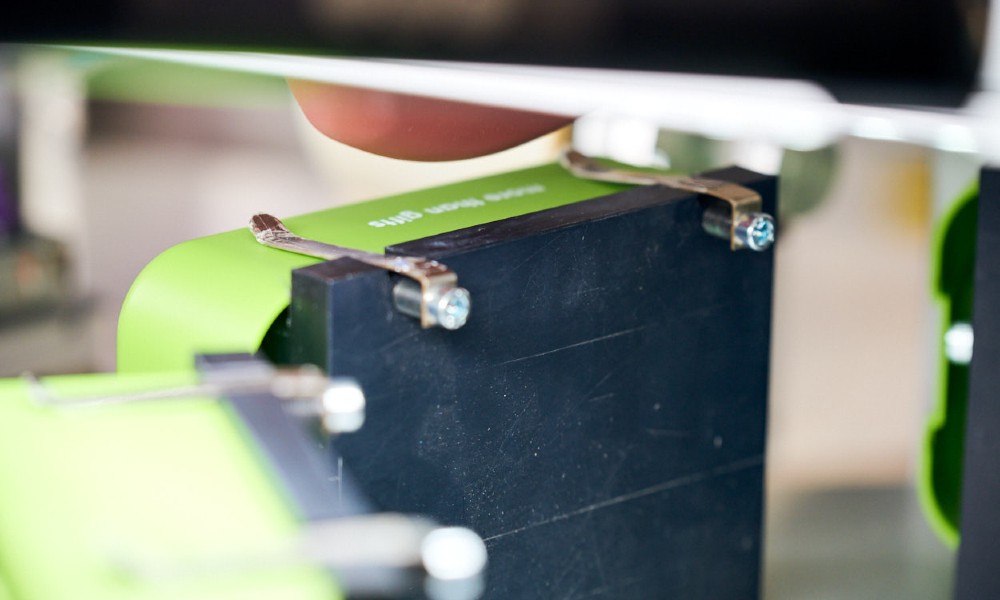

Pad printing

(P0-P7)

Pad printing is a technique where silicone stamps are used to print the logo on the item. With this technique you achieve a sharper finish and a perfect colour matching (PMS) is achievable. Pad printing is the most used printing technique whereby a logo is engraved onto a metal plate and then transferred onto the item using a silicone pad, as ink does not adhere to silicone. Like Screen printing each colour must be printed separately.

Advantages

- All kind of materials can be printed

- All kind of shapes can be printed

- Pantone colours

- Detailed finish

- Dishwasher proof on glass 30 cycles, 50 degrees

Materials

Due to the wide range of inks used in this process, almost all materials can be printed with this technique.

- Plastics

- Polypropylene (PP)

- Polystyrene (PS)

- Polyethylene (PE)

- PVC

- Metal

- Glass

- Ceramic

- Wood

- Paper

Items

Almost any kind of shape or item in the world can be printed by the pad printing technique. That is why this is the most used printing technique in our business.

- Pens

- Desk clocks

- Business card holders

- USB sticks

- Ceramic mugs

- Memo clips

- Key chains

- Plus many more

Good to know

- Only Pantone (PMS) colours possible without gradients

- Up to 4 colours

- Posttreatment required for hard plastics, metal items, soft touch items